A Composite Engineer has expertise in composite materials, including their properties, fabrication techniques, and testing procedures.

Composites are used in an Aerospace and Defence Manufacturing Company to develop and manufacture composite components for aircraft, spacecraft, and defence systems.

Responsibilities of a Composite Engineer are:

Design and Development:

A Composite Engineer collaborates with design teams responsible for Component Engineering Teams to conceptualize and develop composite components that meet specific performance requirements. He considers factors such as weight, strength, stiffness, fatigue life, and environmental resistance to ensure the component’s suitability for the intended application.

Material Selection and Analysis:

He is knowledgeable in selecting appropriate composite materials based on the component’s functional requirements. He also performs analytical studies to optimize the material properties and design for maximum performance and efficiency.

Fabrication Process Development:

Develop and refine fabrication processes for composite components, ensuring adherence to industry standards and quality control measures. Oversee the selection of moulding techniques, curing parameters, and quality control procedures to produce components with consistent properties and meet performance specifications. This requires the Composite Engineer to be knowledgeable of the various fabrication process for composite components.

Testing and Evaluation:

Conduct or supervise the testing of composite components to evaluate their mechanical properties, fatigue life, and environmental resistance. Analyse test results and identify areas for improvement in the design, material selection, or fabrication process.

Troubleshooting and Failure Analysis:

- Investigate component failures or anomalies to determine the root cause.

- Implement corrective measures to prevent recurrence.

- Conduct failure analysis using analytical tools and experimental methods.

Continuous Improvement and Innovation:

Stay abreast of advancements in composite materials, fabrication techniques, and testing methods.

Actively participate in research and development initiatives to introduce innovative solutions that enhance the performance and cost-effectiveness of composite components.

Collaboration and Communication:

Collaborate effectively with design, engineering, and manufacturing teams to ensure seamless integration of composite components into the overall system. Communicate technical information clearly and concisely to stakeholders, ensuring alignment and consensus on design decisions and fabrication processes.

Composites engineers play a vital role in the aerospace and defence industries, ensuring that composite components are lightweight, strong, and durable enough to meet the demanding requirements of these applications. Their expertise and innovation are essential for the development of next-generation aircraft, spacecraft, and defence systems.

Key Responsibilities:

- Creating process plans for the fabrication, assembly, and testing of aerospace and defence components and systems.

- Composite engineers may lead or participate in project teams to develop and manufacture composite components.

- Composite engineers may develop and implement quality control procedures to ensure that composite parts meet the required specifications.

- Composite engineers who work in shop floor may be expected to participate in providing inputs to conduct research and development to improve existing composite materials and manufacturing processes or to develop new ones.

A Composite Engineer can work for the following Companies:

All OEMs will have several projects which involve composites and aerospace and defence engineering is a field with several opportunities for is a high paying and professionally satisfying job.

Boeing (India)

Airbus (India)

Basic Qualifications:

- Bachelor’s Degree in Mechanical Engineering or Aerospace Engineering

Which Include the following courses –

- Engineering mathematics: This includes calculus, linear algebra, and differential equations.

- Engineering mechanics: This includes statics, dynamics, and mechanics of materials.

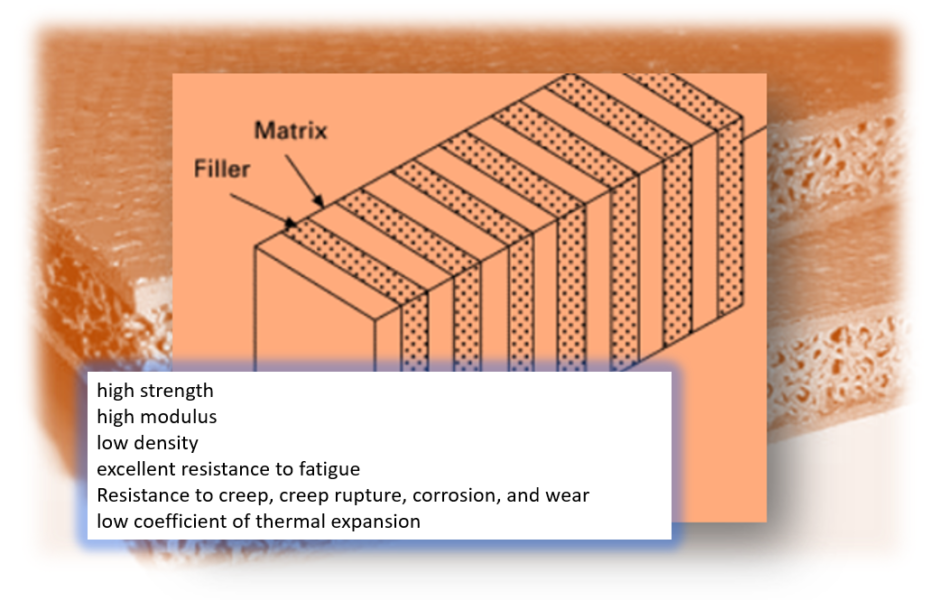

- Materials science: This includes the study of the properties and structure of materials, such as metals, ceramics, and polymers. In-depth.

- Composite materials: This includes the study of the design, fabrication, and properties of composite materials. In-depth.

- Manufacturing processes: This includes the study of the various methods used to manufacture composite parts.

- Engineering design: This includes the principles and methods used to design engineering components.

Software Expertise:

There is no job today which does not need software expertise. In the domains of Aerospace and Defence management, methods engineer is concerned with creating preferred workflows and executing the projects.

Finite element analysis (FEA) software:

FEA software is used to analyze the stress and strain distribution in composite components. This software helps engineers to ensure that components can withstand the loads they will be subjected to in service. Some common FEA software programs used by composite engineers include:

Unique features of the Job

- Highly specialized

- Experience ensures security of job

- Exposure to current projects

Common Frequently Asked Questions:

- What are the different types of composite materials?

- How are composite materials made?

- What are the properties of composite materials?

- How are composite components designed?

- How are composite components manufactured?

- How are composite components tested?

- What are the challenges of working with composite materials?

- What are the future trends in composite engineering?