The Aerospace component manufacturing Industry is booming in India. The Aerospace giants have started outsourcing to Indian machine shops and Boeing claims it has multiplied its outsourcing to nearly 1 billion dollars.

Why is aerospace business attractive?

- Continuous growth

- Higher profit margin compared to other engineering manufacturing

- Attractive growth path options

- Professional challenges

- Prestigious

India is getting business but the moot question is:

Are profits achievable in aerospace component manufacturing?

Yes, if you can put in the right steps and of course, put in a lot of time.

We will discuss about right steps in this article. The primary requirement are the collection of machines. Let us begin with this.

- Machines to manufacture complex profiles.

- Machines which can achieve close (tight) tolerances.

- Machines which cut hard materials.

- Machine which can produce components at high rate of output. [essentially cutters cutting at high speeds, without chattering].

- Machine which can operate 24 hrs without a breakdown.

- Machine controllers which do not use proprietary language.

- Machines which have high repeat-ability.

- Machines which have internet access.

Profitability begins with machines, but, profitability does not end with machines.

To be a profitable company in aerospace component manufacturing, critical decisions such as hiring senior executives, purchase of machine tools, purchase of software, selecting customers, working culture, and selecting cutting tool suppliers, and choosing orders have to be focused on.

Later on in the article I have listed out around 28 differentiators which will lead to profits.

Firstly, I will discuss about technology and machining and then move on to the above key topics.

The wiki defines machining as “Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process”.

The operative line for this article “Cut into desired final shape”.

Technology is the mechanism used to cut the raw material into final desired shape.

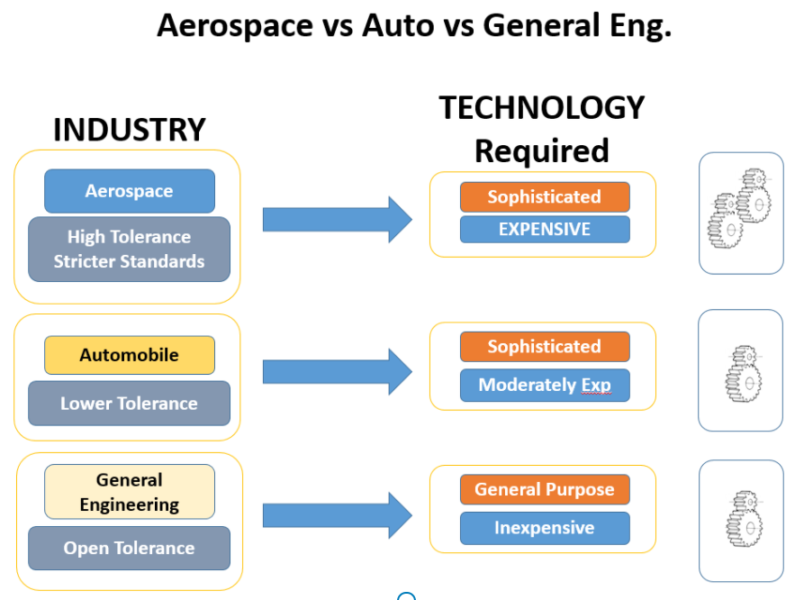

The key point to note here is that the technology required to manufacture aerospace components is different from what is used to manufacture automobile components.

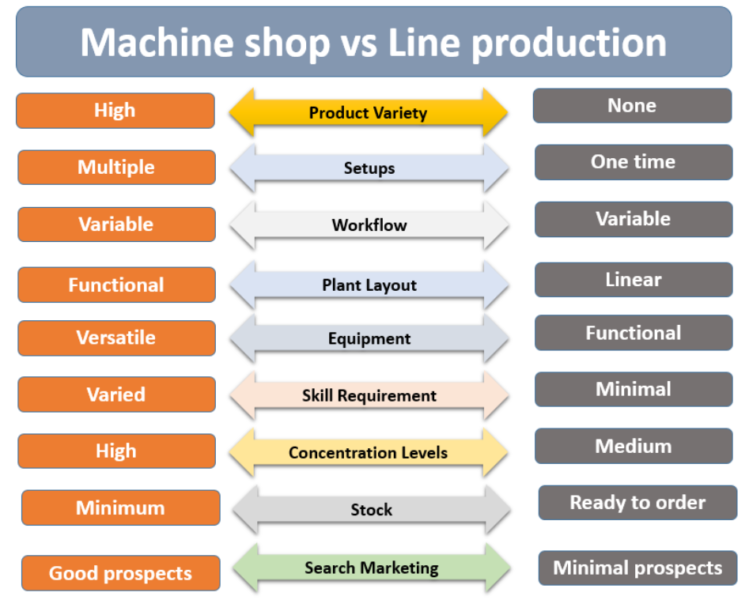

The below picture illustrates this difference. Note that I have included general engineering.

At a broader level while the technology (mechanism) used to manufacture a wider tolerance component is straightforward, the technology required to manufacture a tighter tolerance component is sophisticated.

Machine tools which are used to manufacture aerospace components are available in various price ranges. The best ones are designed to offer tighter tolerances over large number of components over a number of years and these are more expensive. This is the key point.

Any machine shop manufacturing aero components has to be geared towards manufacturing components with tighter tolerance, complex profiles, and hard materials.

Technology is directly related to profits. Most so called experienced machine shop people do not get that if profits is important you need to have the right technology.

Brand Image of Machines and Equipment

Selection of machines also answers another key question a customer would obviously ask. Why should I go to a particular machine shop?

A machine shop with a wide variety of branded machines and equipment offers comfort to customers. Their reasoning is that a particular machine shop which has superior and wide range of machining capability will do their job easily.

The price difference between a top of the line aero specific machine and the regular automobile machine is on the high. This is because the technology is superior.

Is buying such machines justified? You bet.

Purchase of Software

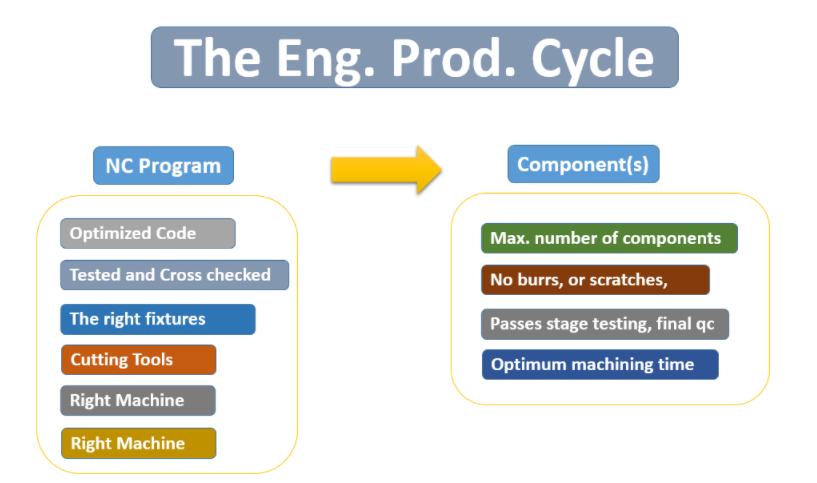

The engineering department is the key department in a manufacturing firm. This is because it sets the ball rolling on a day to day basis or rather order to order basis. Why is it important?

- It is here the NC programs are generated which is the output for the shop floor.

- It is here the fixtures are designed.

- it is here the production rate target is set.

Software in the Engineering Section are a critical asset for the machine shop’s profitability. Catalog the NC programs generated for reuse and secure it.

Work Culture

Work culture in a machine shop is an important factor for high production rates and profits. It is the prime responsibility of the plant in charge to create an atmosphere of mutual trust and team work. Creating groups, setting one against the other, can result in bitter experiences and a toxic culture.

Outsourcing is a financial leakage point, and outsourcing is a fertile ground for all unwanted liberties. Tight control is very important, otherwise honest people will be disappointed and will leave.

Chaos in the machine shop can lead to escalation of rejections, costs and wastage. Given that aero component manufacturing involves a lot many processes, co-ordination between staff is very important.

Selecting cutting tool suppliers

Cutting tools are an important part for machine shop accessories. Given the nature of manufacturing, the number of types of tools are many and stocking and securing is very important.

Selection of cutting tools suppliers and vendors is very crucial. Someone who knows which tool to supply for a particular type of component given the profile, material and hardness is to be encouraged. Paying a premium is important. Do not ever go for cheap china supply.

There are people who purchase material and they have the know how and technology to manufacture cutting tools and supply them. They are the best bet – provided they offer breakdown replacement.

Choosing orders

Setup a machine shop and you start getting orders. Which orders to pick and which ones to pass. Of course, you cannot pass them all. But, you can choose ones which best fit into the capabilities of the unit and not put a strain on the infrastructure.

Differentiation

There are many machine shops out there. There are many who operate without a board and a license to function. And, there are better ones. If you do not differentiate you will be lost in the crowd. Do you want it to happen to you?

Ultimately, a machine shop is known by its uniqueness.

This uniqueness is a sum of many differentiating aspects and not by one or two aspects.

Is your machine any other machine shop or does it have something special to it. The question is how to differentiate? Below, I have listed around 30 differentiating aspects.

1. Order Diary

The first differentiation is Order Diary. Every engineer who is coordinating the execution of an order has to maintain a diary. How does this lead to differentiation? The machine shop engineers should know how an order has progressed, the time it has taken, the corrections and updates, the rejects etc. This ensures that the engineer can work with the customer and discuss the progress, clarifications if any, and customer also knows exactly what is happening with his order and when it is scheduled to be finished.

This will ensure and force the customer also to behave responsibly and not change requirements arbitrarily.

Whatever it is, never fight with the customer.

2. Shifts

The second differentiation is the plant should run for two shifts at a minimum and three shifts if possible. Most units run multiple shifts. However, use this option to cater to prime customers. This gives flexibility to the management to schedule the orders. Multiple shifts results in faster and higher production, bring in a culture of teamwork, and requires planning.

3. Categorise customer backed by data

The third differentiation is bump up the orders which are from A category customers. Yes, have a running list of A, B, C category customers ranked based internal evaluation. Deliver early and impress them. Customers will love to get more of those aha! moments..

There are different types of customers a machine shop gets. Broadly, there are two categories. One, who are high tech and have big projects themselves. They are good to serve and patronise.

The others are those who are into the business with no technological competency and mainly outsourcing agents. Avoid them as they offer more problems than value and adopt devious means to swindle the machine shop. One common trick is to always have a couple of rejects and thereby avoid payment!

4. Extra Material

The fourth differentiation is try your best not to ask for extra material. Develop a strategy, invest if required to achieve this. Customers love it when you do not ask for extra raw stock. If you achieve this objective for a reasonable period of time, advertise this in a big way. BMW, Benz, achieve such spectacular milestones and build their company on such achievements.

5. Have Unique Packing

The fifth. Have unique packing. Make it a prestigious issue for the unit. Make it attractive so that customers know your unit by your packing. Occupying mind space is important for a business. Think of it. It is true.

6. Treat your customers well

The sixth one, is do treat your customers well. Bargain, negotiate, nudge, but never ill treat them.

7. Conduct welfare events periodically

Next, conduct welfare events. Keep your team together.

8. Conduct self development in the areas which will enhance quality of output

Eighth, train your operators well with weekly classes.

1 hr per week is not much to waste. If good restaurants conduct training programs, why not you a high tech firm. Personal development and learning is critical for everyone. Support it. If you are not yet doing it, you should be worried!

9. Keep noise level down

Ninth, keep the noise level down. If possible quiet. Vested interests create noise – to distract and disrupt. Behind this is a insecure executive.

10. Clannish behaviour

Discourage clannish behaviour. Encourage English speaking – particularly if you have customers visiting. Clannish behaviour can lead to groups and consequence is conflicts. Customers loose confidence when the staff display clannish behaviour.

11. Payments

Eleventh which is very important is try and pay your suppliers promptly. Word spreads in the industry.

12. SOP – standard operating procedure

Twelve, create a SOP list which you follow diligently, display prominently to your visitors. Make sure they see them. It is not about you as an individual. It is your company.

This will also ensure that all your staff know exactly what to do when.

I do agree it is difficult for a country like India, but try it, it will be accepted slowly.

This is followed by all good companies and customers love it when they see one.

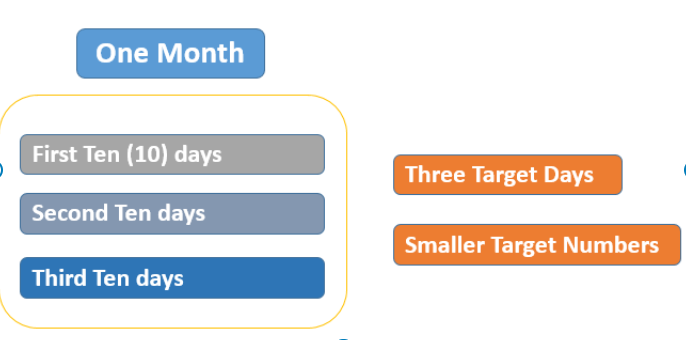

13. Split targets

Next, very important, split monthly targets into convenient target dates.

And, make it known which are the important days. Try and finish the planned orders on the set target days.

14. Achievement motivation

Fourteenth, create a simple hierarchy of designations. Motivate staff to achieve next designations. Introduce your staff to customers in a most polite and respectful way use designations.

15. Information flow

Fifteenth, let your top management know exactly what is happening on the customer front. This will help when there is an unexpected problem. Never keep your management in the dark.

16. Maintain Discipline with customers

Sixteenth, the unit in charge should not bring up personal issues with staff and customers. Usually, it starts with staff and then trickles to customers also. Keep it professional. Customers love serious and focused vendors.

17. Integrity

Never pardon intentionally done wrong purchases. Take some punitive action.

18. Timings

Eighteenth, cities such as Mumbai, Bengaluru, Delhi, Chennai and Hyderabad, have become huge cities and traffic is a big issue. Start early and let your staff leave early. Enable staff to spend time with family. They will be grateful.

18. Business Center

Treat each department as a business center. Do you have a sophisticated QC section. Inform all around your unit of the capabilities you possess. Do you have a good tool and cutter grinder? Offer the service. Keep earning even if it is small amounts. Every penny helps.

17. Controllers

Limit the number of controllers to 3 types. This has big advantages. Why 3 and why not 4, I will take it up in another article.

18. Pre production

Invest in a simulation software.

Saves a lot of headache. Before going ahead with manufacturing demonstrate the cutting process to customer. A good opportunity to impress the customer and ensure there are lesser rejections.

19. Equipment

To maximise pricing – focus on enhancing capabilities in complex profile cutting, achieving closer tolerances, and cutting harder materials.

20. Present well

Keep machine tools well painted and clean. Present a decent picture to customer. It is on those machines their components are manufactured. They would prefer to see a decent picture than a dirty one.

As machines start loosing their capabilities, if retrofitting is not done, the machine shop will eventually have to consider becoming an automobile manufacturing company.

21. Publicise

Keep a simple and well listed leaflet in office. Hand it over to all customers who visit. Many will not know your capabilities! Educate them.

22. Management Model

Use machine shop management model and practises. Do not use line production management model in a machine shop. A machine shop is like a single engine aircraft. Needs continuous monitoring, is not meant for long stretches in one go – frequent checking, greater possibility/risk of failure – many variables and processes, and is exciting – immense job satisfaction because of the challenges it poses on a continuous basis. Reduce cross connections by having a tailor made organisational structure.

23. Have a stable Organisational Structure

Some machine shops operate without a structure. This is because they are small and have fewer people. They are usually a partnership or proprietorship.O

For any outfit with more than 20 staff, an organisational structure is required. To optimise performance, roles and designations have to be clearly marked.

The key point is have a stable organisational structure. Do not change it whenever there is an itch. Let your customer interact with the same people for a minimum period of time.

24. Thin section Components

Many casing components have thin sections. These components have to be secured appropriately (depending on the profile) to prevent warping. When there are large number of components, warping happens and can disrupt the production schedules and result in rework. Take care if there are large number of thin section components in your order book.

25. Search Marketing

Do you have a website? A dedicated url for the machine shop will be a smart move. List all your capabilities and sample components with (appropriate permissions) on the website. And, target markets with a copy focusing on machine shop strengths.

A company I know did some clever internet marketing and was able to get orders from Nigeria. The components they make are pressed components. They are getting a better pricing. Israel is a good target country for customers.

Search for aerospace manufacturing in google and see whether your company is in the top 10 list. If it is not do this:

- Create a unique responsive website

- Connect to a blog

- Blog about your company – daily one post is good enough

- Get identified that you are located in your city

- Create a video and let your CEO talk and address your potential customers

- List and describe all your positives

- Visit and participate in exhibitions – post all pictures and commentary and video

- Use Instagram

- Tweet daily on current trending topics

- Use linkedin and network

Do not neglect search marketing. It can bring in some orders.

26. Creative are Sensitive

Machine shop personnel are Creative people and this is imbibed into the units culture. Treat them with sensitivity and ensure work culture is tuned to enhancing creativity.

27. Target small structural components and assemblies

A significant number of components being outsourced to India are small sized. Differentiate yourself by investing in small sized components. Invest in software, accessories, machine, qc equipment meet such orders.

Do not diversify broadly this will dilute your strengths and will be harder to have a competitive advantage.

If half of the above are implemented remarkable improvements can be observed.

Note that being 100% perfect is not practical nor realistic. But, the pursuit should be towards 100% – one will end up with decent achievements.

Of course, hard work is a must.

Dear Sir,

I went through your Aerospace component manufacturing article , it is very good and put up in a Simple language and systematic approach to manufacturing. It is a good learning experience for a small entrepreneur like. Thanks for a refreshing journey which brought back my engineering days memory.