Are you responsible for PROFITS for your Company? Looking for Rapid Growth in your Company?

Then this is the 12 Rule Checklist for PROFITS, you should read now and use it for your advantage.

For putting your Company on road to PROFITS all you need to do is implement these 12 Rules and you will see results soon.

If you have an existing company which mostly will be the case, just implement those rules you have not yet done.

Out of 12, a score less than 6-7 means you are quite far from your pursuit of profits.

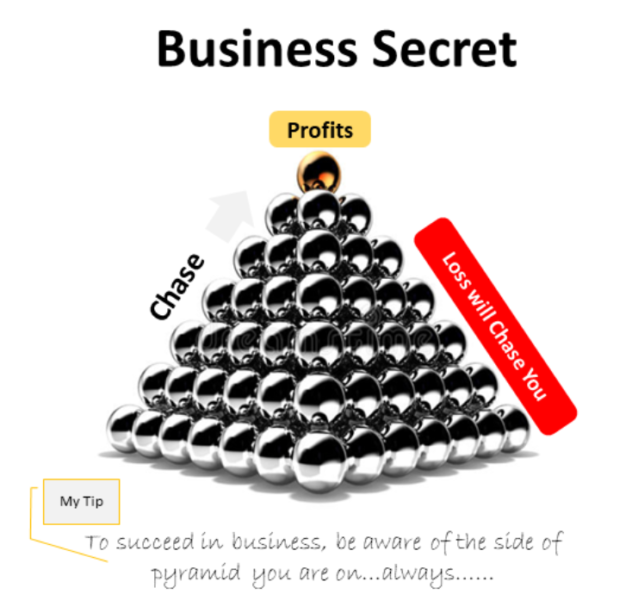

Pursuit of Profits is best depicted in this picture.

Incidentally, I have this picture along with other interesting pictures on main progic page.

To understand exactly what profit pyramid means you need to imagine that everyday, everyone in your company are climbing a hill and trying to reach the peak. The peak is the profit peak.

If not, all of your colleagues and probably you, are sliding downhill, without you ever noticing it.

The gist is, either you chase PROFITs or LOSS will chase you.

Now let us how many points you tick.

1st Rule for PROFITS

Do you have the right Plant Head?

Without a positive, balanced plant head in charge, reaching profits month on month can create havoc in the company. If people are leaving frequently, no new staff is staying for a long time, then it is a sure sign your plant is not capable.

2nd Rule for PROFITS

Do you know how to differentiate your firm?

Differentiation is the name of the game today. If you want your customers to remember your services and company then learn to differentiate.

Simple things like welcoming guests to important things like packaging finished goods are great opportunities for differentiation. The deeper the differentiation the harder it is for companies to keep up and compete with you.

3rd Rule for PROFITS

Do you value time?

Do you come to factory late than others? Are the meetings long drawn out? Are your colleagues good in saving and chopping time in a process?

Do you give enough time to your engineering department to come out with innovative machining routines? Can you sit with your engineering heads and discuss alternative tool paths?

Think it over, this is the most important rule.

4th Rule for PROFITS

Are you geared for quick delivery?

How long does it take for your QC department to measure a component(s) and confirm it for delivery from the time the component is machined?

If your QC takes forever to begin measuring a component, then there is serious trouble.

Go back to the drawing board of process management.

5th Rule for PROFITS

Is the market intelligence network in place?

How many times in a week do you discuss about potential orders with your senior colleagues?

Once a week?

This indicates how strong is your market intelligence.

6th Rule for PROFITS

Is your Engineering department agile?

What is your program to analyse a component? Do you schedule a meeting? How do you assign an engineer to a particular component programming? Is it in a meeting?

How do you allocate work?

A surplus of designs and programs ready for productions means you are ready for profits.

7th Rule for PROFITS

Have you banded your sub contractors?

Do you continuously band your sub contractors. Sub contractors are a critical part of manufacturing. If you do not know your sub contractors well, then you are not running your unit well.

8th Rule for PROFITS

Have you banded your customers?

This is similar to the previous but the yardsticks are different. When was the last time you fought with your customers?

The more you fight and have differences with your customer, the further you are from PROFITs.

9th Rule for PROFITS

Do you hold employee welfare initiatives?

Component manufacturing unlike mass manufacturing requires handling employees differently.

How strong is your HR?

10th Rule for PROFITS

Do you have a policy on rework?

Reworks can eat into profits. How do plan for ZERO rework? Do you have a plan? How dedicated are your teams to go for ZERO rework?

11th Rule for PROFITS

Do you have a plan for stock taking of cutting tools?

How do you protect your valuable assets? Engineering drawings, Component NC programs, Customer Component history, machine tool maintenance history, cutting tool security, employee contributions to profits.

Each of the above is an asset. How do you leverage it?

12th Rule for PROFITS

How good is your machine maintenance program?

Machine tools are the most important physical asset of a manufacturing firm. Do you have a plan to maintain them? How well is the plan integrated to your daily production?

It is a challenge to the shop on how and when to service the machines.

If your score is more 7 you are near profits. Or there is quite a distance.

Any questions? Do call me.

Or post your comments and questions in the section below.