Let us get straight to the point.

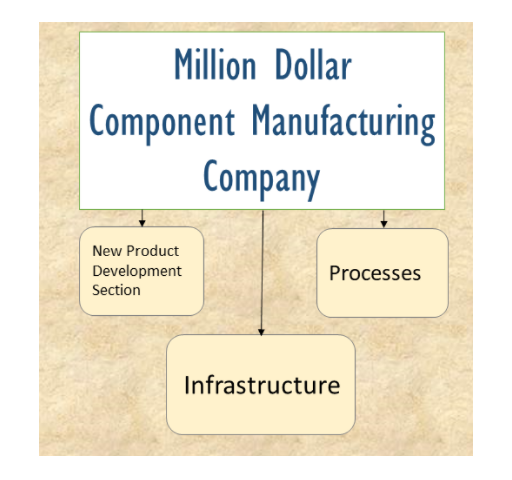

What is a Million Dollar Component Manufacturing Company?

When we say a million dollar component manufacturing company, we are referring to a company which has a fat order book, new product development team is well organized and delivers results, daily production goes on smoothly, simultaneous production of new products in the production shop, work goes on in a clockwork fashion, and importantly all these lead to profits. A million dollar production per month.

Most production shops age over the years. Which really translates to – they prefer to produce large number of components of the same and simple design and keep their machines engaged.

Million Dollar component manufacturing companies are proactive and ensure that this mindset is avoided. Why do they do this? One simple reason is Profits. Instead of settling for same and simple designs they go for New Product Component Manufacturing and ensure Profits and Growth.

This article gives an overview of how to create and manage such a company.

So, how is a Million Dollar unit different from a Regular manufacturing unit?

There are many differences, but if you were to ask me, a single important difference is the New Product Development Section, including the Team and Infrastructure. A regular manufacturing unit is, well regular. It has no new product development section. Such a company prefers to take simple component orders and shies away from new product development and manufacture.

How do we create a million dollar component manufacturing company?

A component manufacturing unit is a metal cutting company which buys raw stock and manufactures a component with complex shapes out of this raw stock.

This is the most simple and basic definition. To be a million dollar company, focus at the plant level has to be on the following three areas.

- New Product Development

- Infrastructure

- Processes

With the advent of 3D printing, a strong new development section will ensure smooth transition into the future.

New Product Development ensures there is a continuous order flow. This is because, OEMs and Tier 1 companies will know that the company can engineer any new component and manufacture the same. This in turn enables OEMs to come out with new designs for their sub systems and systems. So, if India has to become an Aero and Defence leader, it has to have a large pool of such companies and an ecosystem to execute such orders.

Infrastructure which is the next important aspect, ensures orders are executed efficiently.

Processes ensure that every standard practices can be developed and sustained. This is what I call a Million Dollar Company as reaching such a target cannot be done overnight.

Finance is the bottom line. Let us define the million dollar company in Indian rupees.

Which is Re. 6 + crores. The Goal is to create a company which reaches Re. 6 Crore production per month.

Let us discuss each one in detail:

1.New Product Development

Today’s assemblies and finished products change overnight. Boeing, Airbus, Dassault, change their systems constantly. As systems change, components change and designs also change overnight. To achieve their goal of low costs and high power, companies constantly come out with newer and more efficient designs.

To be the preferred manufacturer for complex components, leading component manufacturing units in India, have to recognize this reality.

Which translates to a Strong Engineering Section.

The first thing to understand here is that without an independent engineering section a strong one cannot exist.

For a start, an Engineering Section has to be physically separated from the Production Floor.

With a clear set of rules.

- No Mobiles allowed. (Silly, but very important for security)

- Powerful computers

- Latest versions of software – one or two licenses are enough

- No loading of licensed versions on Laptops

- A right mix of youngsters and experienced

- Silence

- No loading of components after completing programming first and every subsequent pass

- Diarize

- Morning Meetings different from that for production

- No interruptions

- Career growth opportunities within the section

- Independent recruiting policies for Engineering

- Creativity rewarded

- No creativity penalized

- Trying with cross check rewarded

- Constant and Continuous Training

- 1:2 Trainees : Regulars

- Start Early every day

- Follow the 10 day, split target

- Use subscription model for software

Once the above discipline measures are implemented, we are all set to move to the next stage.

One may want to know how long will it tale implement the above 18 measures. In my opinion, half a day, with a tea break. 1st session to convey and discuss. 2nd session to take feedback and conclusion.

The Engineering Section in charge has to be made accountable for implementing this.

Why are these rules important?

We need to understand that new product development is a creative job. For creativity to happen, a fairly secure and disciplined atmosphere is needed.

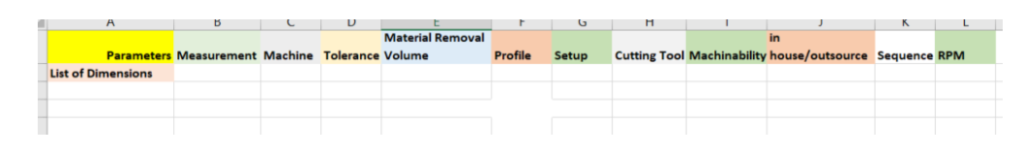

The next step is Component Analysis.

Most new product development teams deploy various methods to do a component analysis. Some leave it to individuals to come up with a NC program. This can be self defeating. Thankfully, there are simple tools to do a thorough component analysis.

One such is the dimensions analysis approach. In this approach, all dimensions are named and listed in a column and factors such as tolerance, machinability, steps, cutting tools, sequence, rpm, setup, number of passes and so on are listed in rows. The next step is to hold team meetings and run through (iterate) each dimension and draw conclusions.

A spreadsheet with all of the data is a valuable source document for engineering a new component and production.

A key tool to understand the component better is the sorting and grouping tool.

When do you the Analysis Sheet?

A thumb rule to use the analysis sheet when the dimensions on the component are more in number and more than two or three dimensions are complex.

Why do you do the Analysis Sheet?

To get the component done in the shortest possible time. The second objective is to get higher profits – which is direct result of cutting costs of engineering and production to the minimum.

Time and money, are the key factors for profits. A capable New Product Engineering Section has a direct influence on Profits.

Once, we are done with component analysis, we can move on to the next step.

The next step is the First Principle. With this step we are making decisions which are going to impact all the future steps. So, people of integrity and calmness are required in the process. While haste will result in wrong decisions and in-ordinate delay, lack of integrity will sabotage the entire process from the beginning.

So, what is the First Principle?

Firstly, let us be clear that the first principle can vary from component to component. Like the first scene in a movie varies from movie to movie.

The first principle is the question you need to frame and answer for a particular component.

If you can frame the question properly you can be rest assured you are on your way to complete the component.

The Answer to the Question is the First Principle.

The questions can be what is the tool you need to use to cut a dimension in a component from among several dimensions in the component. Or it can be, what is the machine to use to cut a set number of dimensions. Or it could be, what is the fixture you need to use for machining the entire or first set of dimensions in a component.

The second principle follows the first and so on.

A component manufacturing company has to have the collective skills to take the the above tasks in rapid succession meaning development of the designs and finalizing processes to manufacture the product, internalize the same and secure the same to gain market leadership.

Firstly, for every set number of orders, some components require development work, some don’t. On the surface, it will look like all components need development work. It is not really so. Some components require simple development work some need higher level of skills to development the component.

Finally, you need a leader who knows how to creatively manage a team consisting of Production Head, Design Head and NC programmer, shop floor supervisor, and the cutting tools man.

The leader is like a movie director. It is a creative job, cannot be taught.

This means the plant head needs to have the skill to discern the difference, and can instinctively tell, which component is difficult to develop and where should the energies be focussed.

If you look at the component manufacturing business in India, you will notice that those companies which can take up new product development are the leaders. Those who cannot, take easier components to manufacture, where the competition is intense, and consequently profits are low. In the long run, this can drag the unit to a level where they loose the ability to take up new product development resulting very slow or no growth.

Software

If the first three steps – Set of Rules, Component Analysis, and First Principle are implemented properly, the role of software engineers gets due importance. This is very important as no one is important than the other as this is a team work.

Being a new component development activity, the software required are PowerMill and NX which offer a set of features much needed tools.

To put it one sentence, the software end to end visualization of machining process. With the input being component drawing, the software enable tool path simulation, efficient roughing capabilities, vast set of libraries to choose from, and preset libraries for machining specific impeller and such.

For the discerning, it is obvious that what the software does is all repeatable processes are created and offered as libraries.

But, the department focus is new product development. So, the idea that software will do our job of engineering new products has to be kept aside. Effective utilization of software will happen only if the first three steps are done properly.

Execution of the 4th step results in the program and the G Code to be fed into CNC machine.

The outcome of the new product development team, is the setup sheets, process sheets, nc program, fixture design, cutting tools, machine, and machine speed.

With this in hand, we can move into machining of components utilizing the infrastructure.

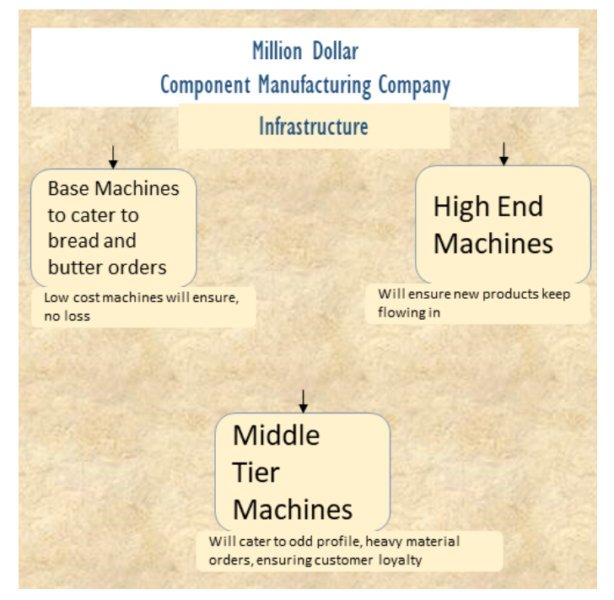

2.Infrastructure

A component manufacturing company infrastructure setup has to be in such manner that can face multiple challenges.

The first challenge is the infrastructure should be such, wide variety of components can be manufactured.

Why is this important?

Simply because, customers should feel and know that in a particular unit a wide variety of components can be manufactured. This will ensure, continuous flow of orders.

The second challenge is ability to manufacture regular components. When I say regular, I am referring to bread and butter components. These components ensure there is a continuous sale being done every month, profits may not be high, but sustain the unit. I suggest that managements should ensure that these components are done by low cost NC machines and not high cost CNC machines. The difference in cost of NC and CNC machines is almost 9 to 10 times the price of a NC machine.

Selection of machines is an art and lays a long term impact on the company. Suppose, the production shop has 25 machines, machines have to be selected based on the following criteria.

- Material Profiles which the component focusses on

- Material hardness which generally come in for production

- Engineering team capabilities available in the region (for competitive advantage)

- Machining capabilities required by premier clients

- History of production (if any)

- Outsourcing capabilities available

3.Processes

Most Component Manufacturing Plant Heads argue that it is not possible to implement processes in a component manufacturing unit.

On the contrary, processes are the key to successfully manage the unit.

Some Production Heads thrive on chaos. Many, including yours truly, do not recommend a chaotic environment. A quiet and systematic working environment ensures growth, as in a development unit, already there will be lot of noise.

This noise is inherent in a development unit, because of the unknown path to successful manufacturing of a component has to be managed to create a million dollar component manufacturing unit.

There are many processes in a component manufacturing unit. With so many process happening independently and simultaneously, it is an opportunity to gain market leadership by streamlining all the processes and enable them to run smoothly.

The key thing to be done is everyone involved in the processes should maintain a diary – in whichever format they find it convenient, with the rider that all data can be provided on requirement.

I can list all the processes and discuss each in detail, but I will save it for another post.

If you have questions post them in the comments section. I will answer them for you.

So, who is this article for?

Operations Head and The Management.

Bringing in the Big Customers:

It is very important that to bring in the big clients one needs a Big Narrative. Build a narrative on the above content, starting with the basic rules, the steps you take to develop new products, how you have structured the shop floor – future secure, and the processes you have built, and the sustainability of the process.

For every customer, ensure you convey the above, they will know where you are and where you are headed.

With the right narrative, you can be sure of convincing your customers, whoever they may be.

This article is an ideal narrative for your big ticket customers.

Read this article on importance of a narrative