Let us face it. Profit is not a Lucky Goal. Not a Lottery, Nor Destiny.

It is a conscious effort with a series of steps done by a company or institution, keeping the Profit Goal in perspective. Sounds simple? It can be, depending on various factors. One factor being how badly you want to show profits every month!!

One has to be committed to achieving profits, to enjoy the high it can give at the end. Single minded.

In this article, I will list out the key factors which will lay the foundation to drive a company which manufactures aerospace and defence components, towards profits.

This is a multi + part article series and you will see how profits have to be pursued and squeezed in each and every step in the process of manufacturing aero components.

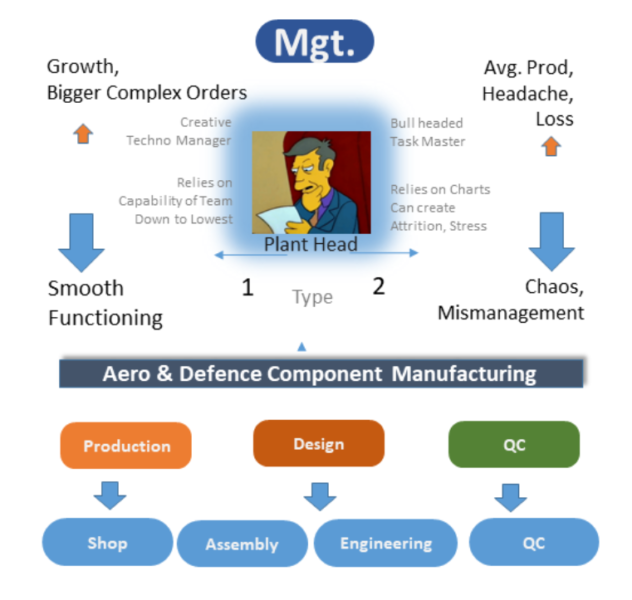

The role of the ADCM – Aerospace Defence Component Manufacturing Unit Plant Head – Plant In Charge is critical in determining whether the unit earns a profit or not.

So, lets jump right in to Aero & Defence Component Manufacturing.

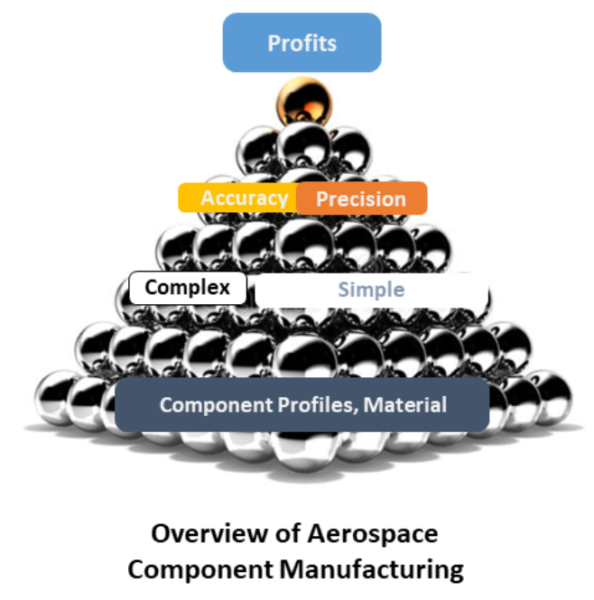

In purely technical terms Aero & Defence Component Manufacturing is all about achieving accuracy and high precision. For sustained success, month on month, year on year, rigorous procedures and documentation can also be added into the list.

So, accuracy and precision, rigorous procedures and documentation are the basic tenets on which a ADCM unit will succeed.

The above pic is a simple illustration of how aero component manufacturing and profits stack up. As we go along in this multi part article, the picture will become complex.

Component profile and material, make up a component’s attributes. The combination of these attributes components can be categorised as complex or simple.

Complex components usually have high tolerances or profiles, or both. Based on these factors and availability of machines determines the possibility of manufacturing a component.

The first check is whether a component can be loaded in a facility.

To restate, when a RFQ comes in, the first two attributes which have to be considered are:

- Material of the component to be manufactured

- Profile & Tolerance

Once, the above details are noted, the next factor to be checked is the in house vs outsourcing issue.

To achieve profits, 60% – 70% of processes on a component has to done in house. If in house machining time on a component is less than that, acceptance or drop has to be decided on a case by case basis.

Once, we pass this stage, comes the issue of receivables.

Customers who promptly pay on time have to be given the most competitive price. Further, we have to also consider the size of the order. This is where the plant in charge’s abilities come into play. He has to make a value judgement before quoting for an enquiry.

After all, delay in receivables results in higher costs eating into profits.

There are other factors also, which are in play. Such as, whether the particular RFQ is for a testing project, critical or a repetitive order.

The plant in charge should also be aware of customer grading.

This is crucial, from the profit perspective as maximum profit the plant makes on a particular RFQ is decided here.

From then on it is one watchful process management exercise of whether profit or lesser than estimated profit is made on a particular RFQ. [An RFQ can have multiple line items].

The role of the Plant In Charge comes into consideration from this stage. He should be able to guide his RFQ team to be transparent and keep unit’s interest upmost.

More truthful the plant in charge is to himself and his team, the expected profit can be achieved.

Or else, it is a continuous downward slide from then on.

Needless to say, the Plant In Charge has to be patient, and a bit wise also, for he has to consider multiple factors, including, the number of orders in process, in pipeline, and so on.

I keep stressing on this factor as Aero Component Manufacturing is not a mass production unit. Where processes are more set, and tracing problems, indiscipline, misinformation and pilferage can be done using established techniques.

Profits are also dependent on the diverse range of components the plant can manufacture. So, machine selection is important. Table size, spindle speed, table traverse and importantly tool holding setup determines the RFQ’s which the plant can quote for. Ability to manufacture a restricted or a narrow band of components will severely restrict the plant’s ability to bid and increase monthly production.

The next factor which matters for Profit maximization is process management.

Processes in Aero component manufacturing have to be designed and handled by Techno Manager, whatever is his qualification.

What is required is not a fancy IIT or IIM degree but plain common sense and a people and process leader. Someone, who can guide his team to follow processes and take pride in reaching targets. This is very important as the second rung leadership in a component manufacturing unit will mostly be engineers at the most or diploma holders.

Today, irrespective of qualifications, people have become aspirational. Recently, an engineer resigned from an aero component manufacturing unit. When he called me and told me the reason he left the job, I felt feel sorry for him. He told me, “the plant in charge is short tempered” and gives me roles which I am not recruited or trained for. He also told me there is no atmosphere of learning. Plant in charge has to have a contemporary understanding of today’s employees. Everyone, has a smartphone, knows what is happening around, knows many are leading exciting lives, and expect a decent work atmosphere. They have become aspirational.

A plant in charge, should enable the management to go for bigger orders and grow the company. He should not be asking for working capital, rarely used state of the art equipment, and his own favorites as senior people. Instead, he should shore up the existing facilities, build a team of curious doers, and be an team leader.

Importantly, he should have a knowledge based approach rather than figures based approach.

In the above pic, I have shown how a plant in charge’s role will determine the management plans to expand and grow the unit.

The type 2 plant head will be a stubborn person refusing to hear manufacturing hiccups in the shop floor and figure out solutions for it.

Instead, he will use targets and numbers, probably charts and tables to harass the workers and engineers.

The type 1 plant head will be a techno manager who understands the demands of modern day components and orders and how to get the team to manufacture the components. Each team member will be strong in certain areas.

It may be that one is strong in safe and careful machining, one is good in cutting tools, and another is good in monitoring work in progress.

Can your plant in charge manage such diverse talents?

In an Aero Component Manufacturing Unit, he should be.

Why do I stress on the role of Plant In Charge?

This is because, daily functioning of aero component manufacturing is entirely different from any process management unit. The reasons are many. The main reason is, it is a combination of knowledge of technology, knowledge of machining, taking up complicated components, putting together a team and leading them to execute complicated components, creative work, task based improvements, and strict procedures to be followed.

In my experience of the past 30 yrs, of selling of software to companies, designs, tool room work, manufacturing process software, consulting, managing production of aerospace unit for a brief period, I have seen repeatedly that unit in charge is the key link between workers and management and makes it easy or impossible for the growth of the unit.

If he is a tunnel vision man the unit will see all kinds of symptoms, such as attrition, daily squabbles, low productivity, constant changing of roles.

Another, important role of a plant in charge is to spot new business opportunities if needed.

For instance, as I write this article, Corona has affected normal life since 150 days. Has the team discussed with the management possibility that aerospace business may shrink? What is the way forward? Is a short term strategy shift needed?

Why do I stress that a Plant In Charge should be trained in Technology Management?

Let us consider Controllers which control the Machine Tool. It is a computer of sorts.

Controllers are electronic and software units which control the movement of tools, table, rotation of tools, speed of spindle, pause, on, and off.

A plant in charge should know how CNC Controllers impact productivity.

This may be alien to many. Controllers are linked to productivity, which is linked to Profits. The in charge should be aware of this aspect, also.

In summary, managing an Aerospace Component Manufacturing Unit, requires knowledge and genuine experience of technology, its impact and role, knowledge of machining and how technology is changing machining methods, how to manage shop floor workers who do creative work and right language to be spoken with them, how to recruit right people for the right position, how to work with RFQ person and senior team to run the plant, how to work with key senior people without hurting their egos, and how to be a trust executive for the management.

In the upcoming articles, I will write about 50 topics which are important for successful functioning of an Aerospace Component Manufacturing Unit.