They possess expertise in structural mechanics, materials science, and finite element analysis (FEA) software. A Structures Engineer in an Aerospace and Defence Manufacturing Company plays a crucial role in designing, analyzing, and ensuring the structural integrity of aircraft, spacecraft, and defense systems. They possess expertise in structural mechanics, materials science, and finite element analysis (FEA) software.

Their primary responsibilities encompass:

Structural Design and Analysis: Structures engineers collaborate with design teams to conceptualize, design, and analyze the structural components of aircraft, spacecraft, and defense systems. They consider factors such as weight, strength, stiffness, fatigue life, and environmental resistance to ensure the structural integrity of the system under various operating conditions.

Finite Element Analysis (FEA): Structures engineers utilize FEA software to create and analyze detailed structural models of complex components and assemblies. They simulate various loading scenarios, such as aerodynamic forces, inertial loads, and thermal stresses, to predict the structural behavior’s and identify potential failure points.

Material Selection and Optimization: Structures engineers select appropriate materials for structural components based on their properties, such as strength-to-weight ratio, stiffness, and environmental compatibility. They optimize material usage to minimize weight while maintaining structural integrity.

Stress Analysis and Fatigue Life Assessment: Structures engineers conduct stress analysis to determine the stress distribution within structural components under various loading conditions. They perform fatigue life assessments to predict the component’s lifespan under cyclic loading.

Structural Testing and Validation: Structures engineers oversee structural testing to validate the design and performance of structural components and systems. They analyze test results to identify discrepancies between analytical predictions and actual behavior’s.

Troubleshooting and Failure Analysis: Structures engineers investigate structural failures or anomalies to determine root causes. They employ analytical tools and experimental methods to diagnose problems, such as material defects, design flaws, or manufacturing defects.

Compliance with Standards and Regulations: Structures engineers ensure that structural designs comply with relevant industry standards, regulations, and safety codes. They stay informed about changes in standards and implement necessary updates to maintain compliance.

Technical Documentation and Communication: Structures engineers maintain detailed documentation of structural designs, analysis results, and test procedures. They effectively communicate technical information to stakeholders, including system designers, manufacturers, and regulatory bodies.

Additional Responsibilities:

Continuous Improvement and Innovation: Structures engineers stay abreast of advancements in structural materials, analysis techniques, and manufacturing processes. They actively participate in research and development initiatives to introduce innovative solutions that enhance the performance, efficiency, and reliability of structural systems.

Integration with Other Engineering Disciplines: Structures engineers collaborate closely with other engineering disciplines, such as aerodynamics, propulsion, and systems engineering, to ensure seamless integration of structural components into the overall system architecture.

Weight Management: Structures engineers play a critical role in weight management by optimizing structural designs to minimize weight while maintaining structural integrity. This is crucial for improving the performance and fuel efficiency of aircraft and spacecraft.

Structural Certification: Structures engineers prepare and submit documentation for structural certification to regulatory bodies, such as the Federal Aviation Administration (FAA) for aircraft and the National Aeronautics and Space Administration (NASA) for spacecraft.

Overall, Structures Engineers play a critical role in the aerospace and defense industries, ensuring the structural integrity and safety of complex systems that operate under demanding conditions.

Key Responsibilities:

- Creating process plans for the fabrication, assembly, and testing of aerospace and defence components and systems.

- Constant reskilling of structural mechanics, materials science

- Expertise in finite element analysis (FEA) software

Companies a Structures Engineer can work for:

All manufacturing companies have openings for project managers / engineers. Companies which manufacture, fighter aircrafts such as Tejas, Rafale, helicopters Prachand, Apache, tanks like Arjun.

Basic Qualifications:

- Bachelor’s Degree in Mechanical Engineering or Aerospace Engineering

Software Expertise:

There is no job today which does not need software expertise. In the domains of Aerospace and Defence management, methods engineer is concerned with creating preferred workflows and executing the projects.

Here is a list:

Unique features of the Job

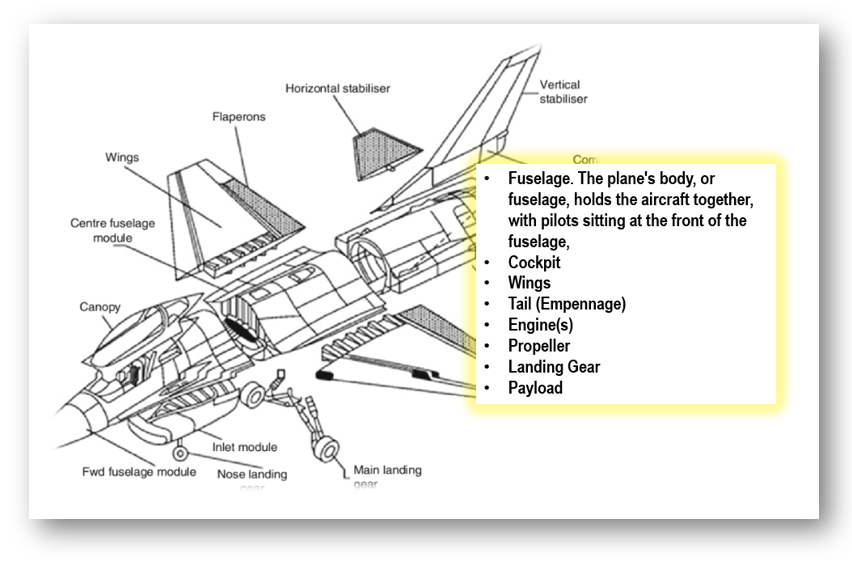

- End to End knowledge of how aircrafts are designed and manufactured

- Various inflight and assembling issues

- The certifications which go into getting an aircraft off the ground

- Working on long duration projects

Common Frequently Asked Questions:

- Are there many companies which recruit Structures Engineer?

- Are project management skills required for a Structures Engineer?